POSITIONING

STRAIGHTNESS AND SQUARENESS

LASER BALLBAR AND DYNAMICS MEASURES FOR SERVO-SETTINGS

LASER BALLBAR AND DYNAMICS MEASURES FOR SERVO-SETTINGS

LICS 300 H

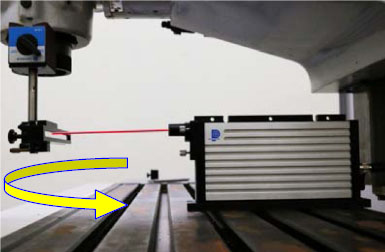

Laser Doppler Displacement Meter

This new calibration system, based on the patented Laser Doppler Displacement Meter (LDDMTM) technology, is designed for easy setup and operation. The basic system, including a laser head and a retroreflector for displacement measurement; a quad-detector and an optical square for straightness and squareness measurement; and a flat-mirror and an optical adaptor for dynamic contouring measurement, fits in two small carrying cases.

The Windows software, running on any Notebook computer, is user friendly and is designed to collect and analyze data in accordance with a variety of industry standards, such as NMTBA, VDI, ISO and ASME B5.54. The laser system is calibrated and traceable to NIST.

MAJOR FEATURES AND BENEFITS:

Compact and light-weight

Single-aperture for easy alignment and set-up

Automatic data collection

NIST traceable laser accuracy

WindowsTM software and USB interface

Automatic environmental compensation

Support NMTBA, VDI, ISO and ASME B5.54 standards

Measures Straightness, Squareness, and Parallelism

Non-contact measurement of velocity, acceleration, vibration and circular contours

Volumetric positioning error measurement and Compensation of CNC machine tools and CMMs

Quality control and maintenance

Ultra precision positioning

Alignment of linear guide and machine bed